- TOP

- Resistance Welding

- Products

- Resistance Welder Inverter Model NRW-IN400PA

Resistance Welder Inverter Model NRW-IN400PA

Resistance Welder Inverter Model NRW-IN400PA

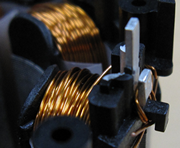

Best choice for magnet wire fusing and copper alloy battery tab welding

This is a highly reliable inverter-type resistance welding power supply that enables high-definition control and installation in an automatic machine. It is equipped with a mode (Free Style Profile) that can optionally set "SLOPE""WELD" and "COOL" within up to 127 steps, enabling precise heat input control required for better bonding of the fusing. In addition, by reducing internal loss and by development of high-efficiency, high-voltage transformer, high current values can be output in a short time, enabling welding of copper alloy battery tabs.

Features

・Switchable Inverter Frequency

The model standard operating frequency is 2000Hz (energization time resolution 0.5ms) with the option to switch to 4000Hz (energization time resolution 0.25ms) or 5000Hz (energization time resolution 0.2ms). The optimal frequency can be selected that realizes high-quality welding with less current ripple based on the workpiece.

・127-Step Free Style Profile

The operator has the option to set "SLOPE", "WELD" and "COOL" arbitrarily with up to 127 steps as a standard feature. Multi-stage slope welding and other multi-stage welding, such as pulse 63-stage welding, are possible. This feature allows high quality joining by precise heat input control for both resistance weld and resistance heat applications.

・1 ms Variable Weld Stop Control

Reduce the margin of error in the workpiece displacement.

・Multi-Transformer Suppor

The Trans Switch option allows the user to connect up to 4 transformers to one welding controller power supply using a transformer switch. With this option multiple welding processes can be implemented using a single welding controller and multiple transformers.

This provides the client with maximum flexibility while maintaining production capacity and capabilities. In addition, equipment installation costs can be reduced and the load on power equipment in the factory can be reduced (load leveling).

Simultaneous pressurization, sequential welding and installation of equipment for multiple processes are also possible.In addition, the Transformer Relay Box option allows the user to connect to existing transformer models.

・Welding Parameter Compensation

To perform optimum welding, the standard programmed weld parameters are fine tune adjusted based on changes in room and electrode temperatures. The “base or typical” welding parameters are stored for each program number. During the actual weld, parameters are compensated according to changes in room temperature and electrode temperature as monitored by the system. This allows for more consistent bonds that are not, or at least minimally, affected by changes in the ambient environment.

・Dust-Proof, Reinforced Structure

Automated systems integration is easier using the model program box which includes remote control.

・Multiple Power Supply Capability

The model can operate on three-phase power supplied from AC200 to 480V without changing or modifying the standard system welding power supply.

Multi-Transformer Support

The Model NRW-IN400PA is capable of supporting a maximum 4 trans switchers.

A single power supply can support multiple welding processes, reducing equipment and installation costs as well as saving space.

Applications

Resistance Welding Power Supplies Specifications

| Item | NRW-IN400PA |

|---|---|

| Control Frequency | Selectable from 2kHz、4kHz、5kHz (Select for each PRG No) |

| Control Mode | Primary curent peak value control, Primary curent average value control, |

| Secondery current effective value control, Secondery voltage effective value control, | |

| Secondary power effective value control, Fixed pulse width control | |

| Range of Output Setting | 400A(Duty Cicle 5%)、200A(Duty Cycle 20%) |

| Range of Timer Setting(ms) | 0.0-3000.0(Total time of UP TIME、WELD TIME、DOWN TIME、COOL TIME) |

| Number of Conditions | 255 |

| User Interface (Setting Tool) | Program box |

| Monitoring Function | Avarage value/peak value monotor, pulse width monitor of current, voltage, power, resistance respectively |

| Multi-stage Welding Fnction | 3-phase mode (slope、weld、cool)/free style mode (Max. 127 step) |

| Cooling Method | Air |

| Interface | Ethernet |

| Power Source | 220V specification:3φ AC200-240V±10% 50/60Hz、400V specification:3φ AC380-480V±10% 50/60Hz |

| Dimensions(mm) | W200×D501×H298(Excluding protrusions) |

| Weight | ≒19kg |

| Welding transformer | NT-IN8444B、NT-IN4474A |

*Power cable/weld power cable / weld sense cable / program controller cable are sold separately (Please specify length.)

Resistance Welding Transformer Specifications

| Item | NT-IN4474A | NT-IN8444B | ||

|---|---|---|---|---|

| Power Source | 220V specification | 400V specification | 220V specification | 400V specification |

| Maximum Welding Current | 4000A(Duty cycle 5%) | 8000A(Duty cycle 5%) | ||

| Rated Capacity (Duty Cycle 50%) | 11 kVA | 10 kVA | 36 kVA | 33 kVA |

| Primary Input Voltage | 300V | 600V | 300V | 600V |

| Secondary Open-circuit Voltage | 8.4V | 7.6V | 14.1V | 12.9V |

| Transformer Turns Ratio | 37:1 | 74:1 | 22:1 | 44:1 |

| Input Frequency | 2kHz/4kHz/5kHz | 2kHz/4kHz/5kHz | ||

| Cooling Method | Air | Air | ||

| Dimensions(mm) | W150×D337×H222(Excluding protrusions) | W200×D370×H214(Excluding protrusions) | ||

| Weight | ≒14kg | ≒23.4kg | ||

Options