- TOP

- Resistance Welding

- Products

- Resistance Welder High-reliability Inverter Model NRW-IN900P

Resistance Welder High-reliability Inverter Model NRW-IN900P

Resistance Welder High-reliability Inverter Model NRW-IN900P

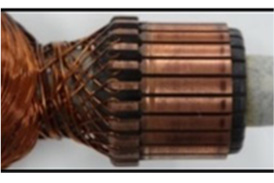

Inverter type resistance welder NRW-900P contributes to improving welding quality of fusing of motors, etc.

Pulsation mode with up to 8 phases and up to 24 seconds of welding and 127-step arbitrary waveform function support various fusing applications.

Newly equipped with weld time monitor and phase monitor, it supports the operation of in-welding compensation function and contributes to the improvement of welding quality

Features

- High capacity with a maximum current of 32000A (When NT-IN32K444 at 400V)

- Long welding time of maximum 5 seconds, 127step arbitrary waveform (freestyle) function (normal mode)

- Pulsation mode suitable for fusing

Pulsation operation of up to 8 phases with UP and DOWN slopes for 24 seconds is available.

Contributes to a wide variety of fusing welding. - Welding stop with variation of 1ms or less by the phase shift function

- Three selectable frequencies (2kHz, 4kHz, 5kHz)

- Equipped with multiple control mode.

Constant current, constant voltage, constant power, primary current peak value, primary current average, and fixed pulse width output control modes are provided. - Built-in welding monitor function

In addition to the average and peak values of current, voltage, power, and resistance, and limit monitor judgment results, the new weld time monitor and phase monitor enables compensation function during welding. - Welding waveform display function

It is effective in improving work efficiency in setting welding conditions and investigating the cause of abnormalities. - Supporting automated machine

Analog input control mode enables real-time control from a PLC. Combined with a temperature sensor, constant temperature control is also possible.

In addition, the program box enables remote control, which allows for greater flexibility in layout when incorporated into facilities. - Compensation function during welding

Output value can be changed instantaneously by external signal input during the welding.

It can be used in combination with displacement sensors, etc., to improve the finishing level.

Application example

Specifications

Resistance Welding Power Supplies Specifications

| Item | NRW-IN900P |

|---|---|

| Control Frequency | Selectable from 2kHz、4kHz、5kHz (Select for each PRG No.) |

| Control Mode | Primary current peak value control, Primary current average value control, Secondary current avarage value control, Secondary voltage avarage value control, Secondary power avarage value control, Fixed pulse width control. |

| Maximum Welding Current | 900A(Duty Cycle 5%) |

| Range of Timer Setting | Nomal mode: 0.0-5000.0ms(Total of UP TIME、WELD TIME、DOWN TIME、COOL TIME) Pulsasion mode: 0.0-24000.0ms(Total of PULSE TIME、COOL TIME) |

| Number of Conditions | Normal mode: 255 Pulsasion mode: 15 |

| Welding Waveform Setting | Normal mode: 3-phase(slope、weld、cool)、free style(Max. 127 step、8-phase) Pulsasion mode: (Max. 120 wave、10000 pulse、8-phase) Analog input control mode: (8-phase) |

| User Interface(Setting Tool) | Program box |

| Monitoring Function | Average value/peas value monitor of current, voltage, power resistance respectively. Pulse width, welding time monitor, phase monitor, Source voltage monitor. Waveform display |

| Cooling Method | Water cooling (Volume of water 3.0ℓ/min) |

| Interface | Ethernet |

| Power Source | 220V:3φ AC200-240V±10% 50/60Hz、400V:3φ AC380-480V±10% 50/60Hz |

| Dimensions(mm) | W250×D651×H428(Excluding protrusions) |

| Weight | 30.4kg |

| Welding Transformer | NT-IN32K444 |

Resistance Welding Transformer Specifications

| Item | NT-IN32K444 | |

|---|---|---|

| Power Source | 220V | 400V |

| Maximam Welding Current | 19800A(Duty Cycle 5%) | 32000A(Duty Cycle 5%) |

| Rated Capacity (Duty Cycle 50%) | 89 kVA | 130 kVA |

| Primary Input Voltage | 300V | 600V |

| Secondary Open Circuit Voltage | 14.1V | 12.9V |

| Transformer Turns Ratio | 22:1 | 44:1 |

| Input Frequency | 2kHz/4kHz/5kHz | |

| Cooling Method | Water Cooling 3.0ℓ/min | |

| Dimensions(mm) | W280×D475×H330(Excluding Protrusions) | |

| Weight | 43.2kg | |

Options

Program Box NA-PB100

Easy installation to automatic machines

The program box enables you remote control. Facility design becomes easier.

Welding Monitor QC-450

Built-in welding monitor function

In addition to the average and peak values of current, voltage, power, and resistance, and limit monitor judgment results, the new weld time monitor and phase monitor enables compensation function during welding.