- TOP

- Ultrasonic Metal Welding

- Products

- 10kW Ultrasonic Metal Welder for EV High Voltage Cables

10kW Ultrasonic Metal Welder for EV High Voltage Cables

10kW Ultrasonic Metal Welder for EV High Voltage Cables

While batteries are becoming larger in order to extend the cruising range of EVs, the high-voltage cables used as power cables are becoming larger diameter to improve power transmission efficiency.

In fact, in China, a major EV country, EV vehicles are beginning to be manufactured with high-voltage cables in the 95SQ and 120SQ sizes.

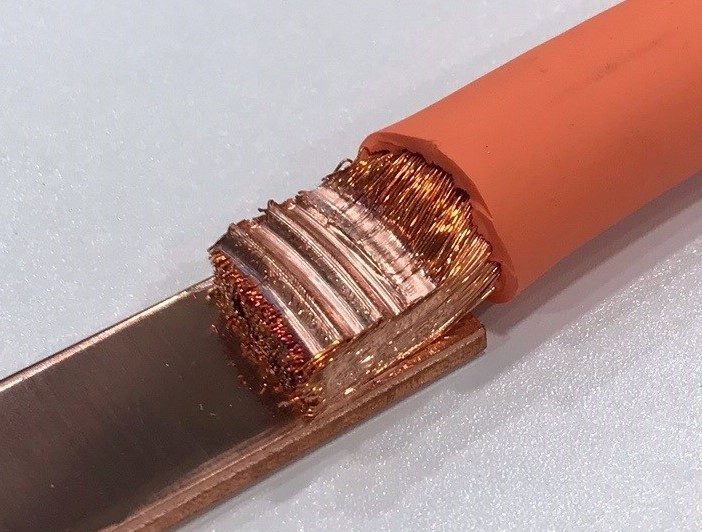

EV High-voltage cables are made of copper or aluminum materials and are directly bonded using ultrasonic metal-joining technology because joining of terminal and wire requires removal of oxide film on surface.

Moreover, not all kind of ultrasonic metal welders can join the target works unless the power is properly used, and the quality of the product will be affected such as cable breakage or lack of strength.

10 kW Ultrasonic Metal Welder is developed with a power output that is suitable for joining 95 SQ copper cables and 120 SQ aluminum cables

Even thick cables can be joined quickly with high accuracy.

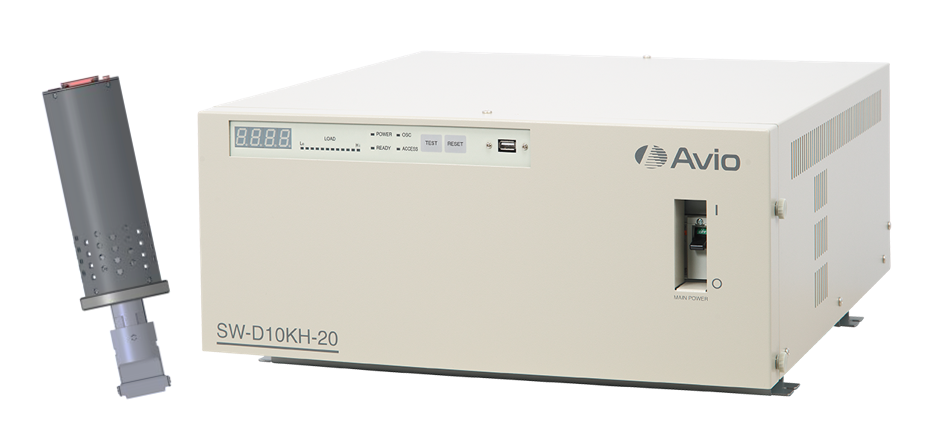

This article introduces features and specifications of the SW-D10KH-20/SH-H10K 10kW ultrasonic metal welder for EV high-voltage cables.

Features of high-power ultrasonic metal welder “SW-D10KH-20/SH-H10K”

Joining time less than 2 seconds

With industry-leading 10,000W output power, 95SQ wire harnesses can be joined in less than 2 seconds*.

*Excluding cooling time

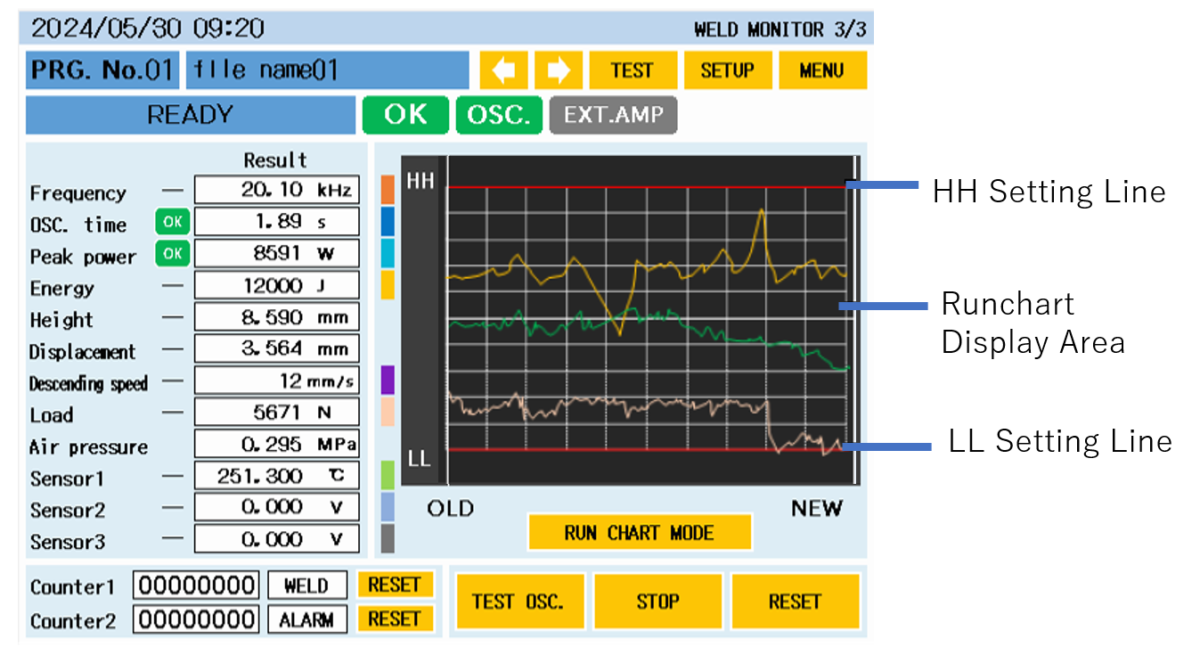

Run chart function for Predicting replacement schedule of horns and oscillators

Run chart function is equipped as standard which monitors joining result with time history.

Centralized monitoring of parameter values and external sensor values improves maintainability of the equipment.

It can also be used to predict when to replace horns and to detect signs of possible failure.

Saving joining result data and data output

Monitor data and graph data can be stored in internal memory.

Data can be checked using screen on the control box, and output to a PC via USB memory, RS 232C communication, or Ethernet communication.

It is useful for traceability

Judgment Function

The SW-D10KH-20 ultrasonic generator is equipped with a comparison function that monitors oscillation frequency, oscillation time, peak power, etc. and compares them with upper and lower limit thresholds.

It can be used for OK/NG judgment and fault detection during production.

External IO interface for automated machine installation

To facilitate integration into an automated machine, an external IO input/output port is provided to monitor and control the status of the ultrasonic generator.

Control BOX UA-C02(Option)

It is used for setting generator (main unit setting such as joining conditions and IP address), software UPDATE, and saving settings to USB memory.

Features

- Intuitive operation:10.4” touch panel LCD (W640xH480)

- Connecting cable :Standard 1.5m, extension cable 3.0m,5.0m,10.0m (Option)

- Hot Swap is supported

- Display: Japanese, English, Chinese are supported

Model for automated machine installation

It consists of ultrasonic generator and oscillator.

The ultrasonic generator detects the start signal from outside and starts oscillation. Joining conditions and equipment settings can be set via RS-232C or Ethernet.

The optional control box UA C02 can also be connected to set the joining conditions and equipment setting

Ultrasonic Generator Specifications

| Items | SW-D10KH-20 |

|---|---|

| Rated Output | 10,000W |

| Frequency | 20kHz |

| Power Supply Voltage | 3-phase AC200Vー240V±10% 50/60Hz |

| Power Requirements | 13,000VA |

| Oscillation Method | Digital Automatic Frequency Tracking Method (D-ATHMOS) |

| Oscillation Control Mode | Timer / Energy / Peak Power / Height / Depth / External Sensor / Continuous |

| Monitor Display | Oscillation frequency, Oscillation Time, Peak Power, Energy, Hight, Depth, External Sensor, Descending Speed, Pressure, Pneumatic Pressure *For external sensor display, unit of voltage, current, and temperature can be changed. |

| Display, Operation | Display on the main unit and on the control box |

| Interface | External IO×1, Analog IO×1, Emergency Stop Output ×2, Interlock×2, RS-232C×1, LAN×1, USB memory ×1 |

| Operating Environmental Temperature | 5℃~40℃ (No freezing) |

| Operating Environmental Humidity | Less than 85% (No condensation) |

| Storage Environmental Temperature | -10℃~60℃ |

| External Dimensions(mm) | W496XD558XH229mm(Including protrusions) |

| Weight | ≒32kg |

Ultrasonic Head Specifications

| Items | SH-H10K |

|---|---|

| Pressure Method | Pneumatic cylinder |

| Min. Pressure | 3,000N |

| Max. Pressure | 10,000N |

| Length Measurement | Linear Scale (0.001mm resolution) |

| Required Pneumatic Source | Dry Air (0.6MPa) |

| Horn Strone | 75mm |

| External Dimensions(mm) | W410xD665xH1045(Incluing Oscillator) |

| Weight | ≒250kg |

Control BOX UA-C02 Specifications

| Items | UA-C02 |

|---|---|

| Screen | Touch panel color LCD W640xH480 pixels |

| Operating Sound | Yes |

| Power Supply | Power supply from the generator |

| Cable Length | 1.5m(Option:3m,5m,10m cable) |

| External Dimensions (mm) | W283xD233xH52(Excluding protrusions) |

| Weight | ≒2.0kg |

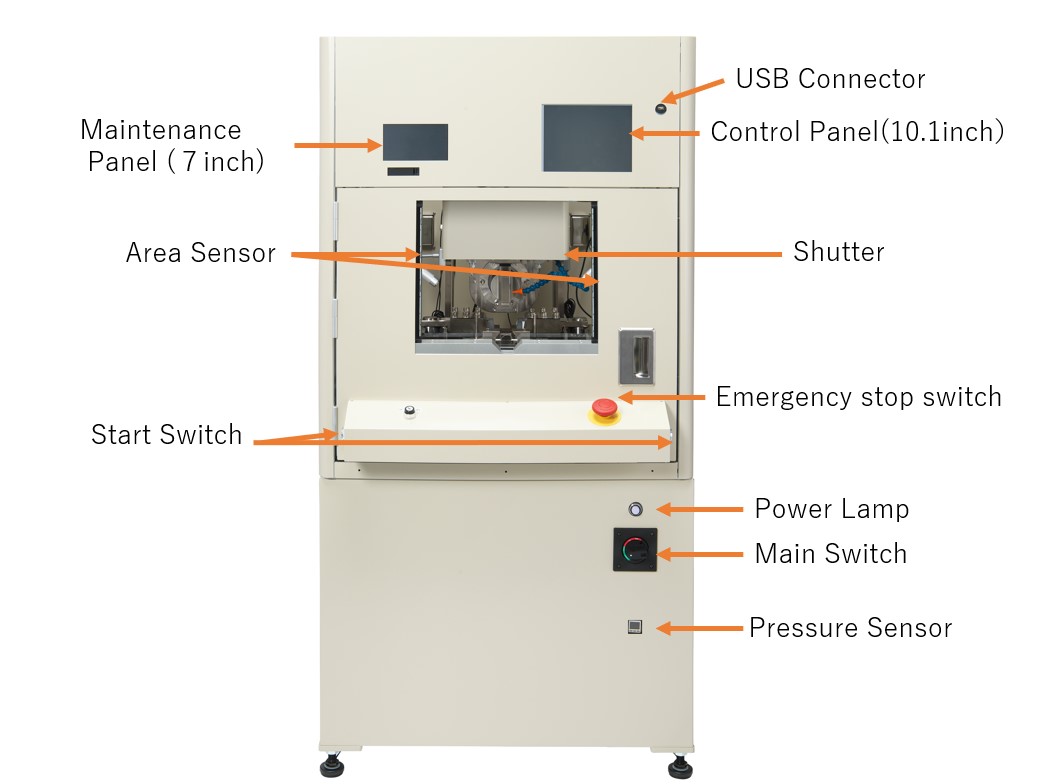

EV High Voltage Cables Welding Machine SE-10K

Dedicated harness welding system incorporating 10kW ultrasonic metal welder SW-D10KH-20.

Features

- Number of joining condition registration: 31

- Recording and external output of production history

- Joining quality judgment function

- Monitoring function

- Graphic display of monitor value

- Run-chart display

- Language display: English, Japanese, Chinese

SE-10K Specifications

| Item | SE-10K |

|---|---|

| Frequency (kHz) | 20 |

| Generator power (W) | 10,000 |

| Weld force max (N) at 6 bars | 10,000 |

| Stroke / Revision stroke | 75mm |

| Outside dimensions incl. HMI operating cockpit (mm) | 906(H)×1833(H)×1214(D) (Excluding protrusions) |

| Control panel (weld process control) | 10.4“/7 " Touchscreen |

| Operating modes | 8 |

| Application memories | 31 |

| Number of stored welds | 100graphics/10,000,000data |

| Number of controllable auxiliary functions (optional) | 3 |

Related video

Please be careful of the volume adjustment as this movie contains sound.