Ultrasonic Welding

- TOP

- Ultrasonic Welding

What is Ultrasonic Welding?

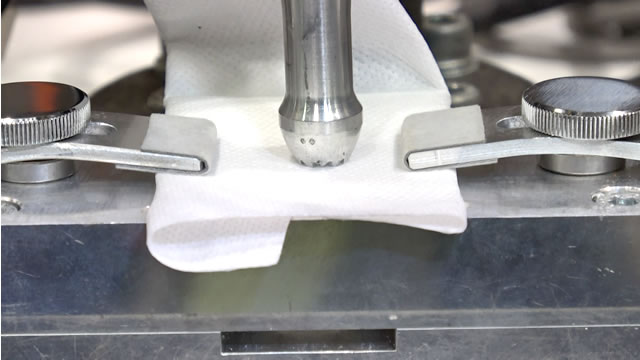

Ultrasonic welding uses ultrasonic vibration and external pressure to melt and join two thermoplastic resin workpieces.

An ultrasonic welding machine consists of an ultrasonic generator that creates high frequency AC to generates electrical energy, an oscillator that converts the electrical energy into mechanical vibration, a press unit that applies pressure and the horn that applies the vibration and pressure to the workpieces to be joined.

Ultrasonic welding is suitable for mass production due to its short welding time (around 1 second) and easy integration into automated processes.

It also creates high quality welds without the use of adhesives or solvents.

This joining solution is used in many applications such as large containers for automobiles and home appliances as well as food and medical packages.

Features of Ultrasonic Welding

Ultrasonic welding is used in a variety of products including automotive, electronics, packaging, textile, and medical.

In addition to welding, it is also used in other processes such as cutting, caulking and gate cutting.

A critical part of any ultrasonic application is to select or design the proper oscillator, horn and jig which operate at the appropriate frequency for the workpieces to be processed.

Application Examples

- Caulking vehicle door trim

- Airtight welding of cases

- Welding and fusing food packaging

- Assembly of fans for air conditioners, etc.

- Cutting of cardboard

Ultrasonic Welding Machine Products

An ultrasonic welding machine consists of an ultrasonic generator that creates high frequency AC to generates electrical energy, an oscillator that converts the electrical energy into mechanical vibration, a press unit that applies pressure and the horn that applies the vibration and pressure to the workpieces to be joined.

Nippon Avionics offers ultrasonic generators and press units which generate frequencies that match the user application needs for the workpieces to be welded or cut.

We also design and manufacture the custom horns to match the application requirements.

Resistance Welding

Resistance Welding Ultrasonic Metal Welding

Ultrasonic Metal Welding Parallel Seam

Parallel Seam  High Frequency Induction Heating

High Frequency Induction Heating