Principle of Ultrasonic Metal Welding

- TOP

- Ultrasonic Metal Welding

- Principle of Ultrasonic Metal Welding

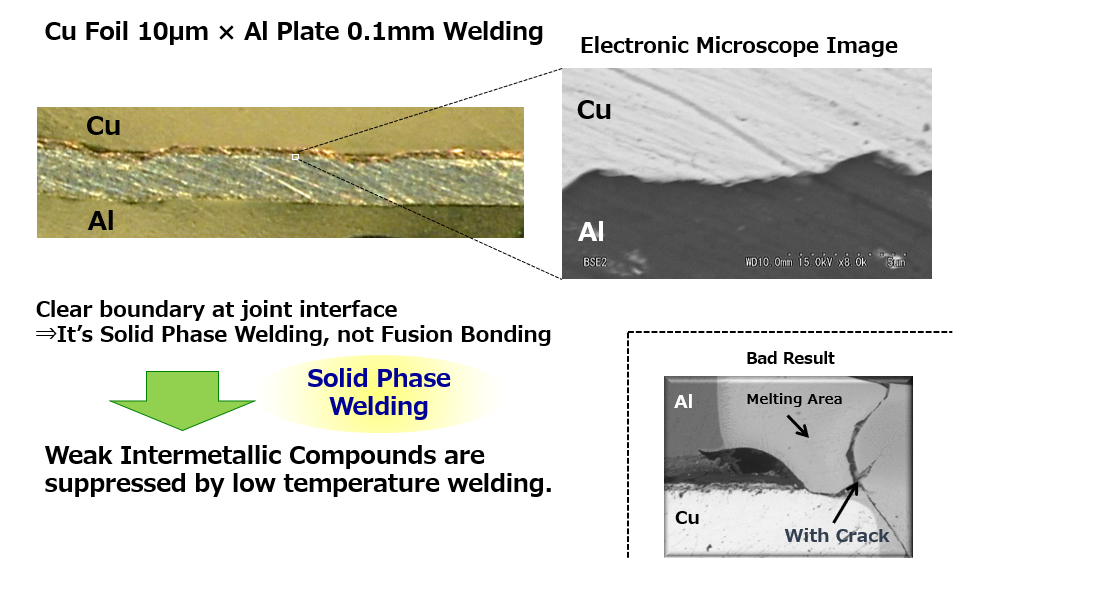

In ultrasonic metal welding, the oxide film on the metal surface is removed by applying ultrasonic vibration to the work, impurities in the surface layer are scattered, and the attractive force between metal atoms is used to create a solid phase bonding state. Since welding performed at temperature of about 1/3 of the melting point, it has small thermal effect to the work.

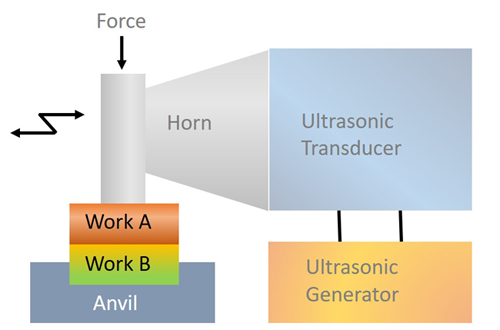

- A high-frequency alternating current is generated by an ultrasonic generator, supplied to the oscillator as electrical energy, and converted into mechanical vibration (ultrasonic energy).

- Ultrasonic energy of an oscillator propagates through a horn, and tip of the horn vibrates in direction perpendicular to pressurizing direction (lateral vibration).

- Metal bonding is possible by applying a head load and ultrasonic vibration to the work (object to be bonded).

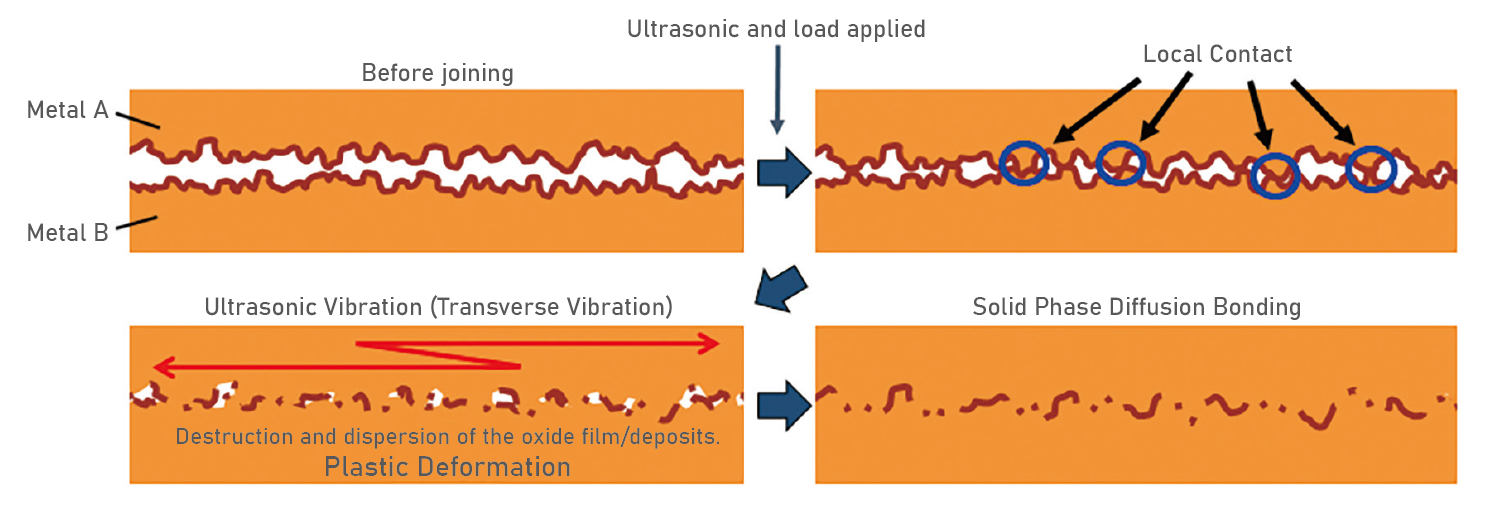

- When metal materials contact each other, local contact occurs at the interface.

- Due to ultrasonic vibration and head pressure, metal interface rubs against each other starting from the local contact point, the oxide film and deposits are destroyed and dispersed, and the clean metal surface is exposed.

- Plastic deformation of surface fine unevenness is promoted, and metal intermolecular attractive force acts due to the proximity of metals to each other, and welding is performed in a solid state (below melting point of the base metal).

Welding of Dissimilar Metals

Resistance Welding

Resistance Welding Hot Bar Reflow Soldering

Hot Bar Reflow Soldering Ultrasonic Welding

Ultrasonic Welding Parallel Seam

Parallel Seam  High Frequency Induction Heating

High Frequency Induction Heating