Parallel Seam Sealing

- TOP

- Parallel Seam Sealing

- Products

- Parallel Seam Sealer with Automatic Lid Placement

Parallel Seam Sealer with Automatic Lid Placement

Parallel Seam Sealer with Automatic Lid Placement

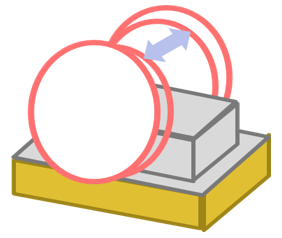

The Parallel Seam Sealer with automatic lid placement is a seam sealing System that can precisely align LID and PKG. It can be used for a wide variety of packages, from crystal devices to large optical devices. It can also be used for packages that had previously been not possible by the seam sealing.

Features

- PKG size: 2 to 150mm

- PKG shape: Round, square, polygonal

- Lid shape: Flat LID,Cap LID,LID with window It supports lid thickness up to 0.3 mm(model:NAW-6100)

It contributes to improve cycle time (Production efficiency)

・Automatic lid placement

・Automatic operation from lid placement to sealing.

・High speed welding (10mm/sec)

It contributes to improve yield.

- It suppresses misalignment with high-precision lid mounting accuracy.

- lid placement accuracy ±0.035mm(25×25mmPKG)

- Model NAW-6100 ensures sufficient seal width to reduce leak defects.

- It reduces heat storage and suppresses cracks.

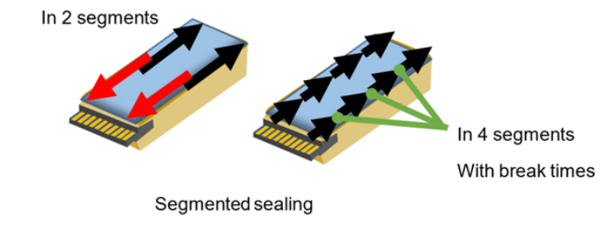

- Optimum control such as split sealing is available which minimizes stress.

Welding start position, end position, and electrode width can be specified by the user.

Functions can be selected according to the production method

- Methods of lid supply

Carrier (standard), cassette, parts feeder, manual placement - Annealing oven

Placement position (left and right), number of stages, number of rows, number of pieces - Adding HEPA filter (Suppresses influence of particle)

Annealing oven

1 row 3 stages

2 row 14 stages

Parallel Seam Sealer Specifications

| Parallel Seam Sealer with Automatic Lid Placement | NAW-6100 Series | NAW-6000 Series |

|---|---|---|

| Rated capacity of welding power supply | 4kVA | 2kVA |

| Head Pressure | 3~22N | |

| Applicable lid thickness | MAX 0.3mm | MAX 0.12mm |

| N2 Gas | 0.2~0.8MPa | |

| Water | 0.2~0.5MPa 1~5L/min | |

| Power Source | AC200V 3Φ 30A | AC200V 3Φ 20A |

| Dimensions | 2100W × 960D × 2000H mm | |

| Mass | ≒650kg | |

* External dimensions can be changed by existence of annealing oven or not, etc.