Pulse Heat (Hot Bar Reflow) Soldering

- TOP

- Pulse Heat (Hot Bar Reflow) Soldering

- Products

- Pulse Heat (Hot Bar) General-Purpose Type TCW-415

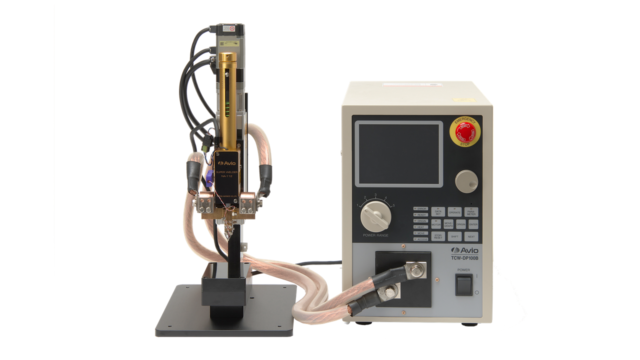

Pulse Heat (Hot Bar) General-Purpose Type TCW-415

Pulse Heat (Hot Bar) General-Purpose Type TCW-415

The best-selling power supply TCW-315, which has been used for various types of joining such as soldering, heat welding, and heat staking, has been renewed.

The TCW-415 general-purpose pulse heat (hot bar soldering machine) offers new features such as heat shift and afterheat settings, enabling higher quality and more stable soldering, heat welding, and plastic heat crimping.

Features

- High Reliability Joining

Because heating and cooling take place while the pressure is being applied, the work position will not be shifted during joining.

- Variable Temperature Profile

Because the heating is local and instantaneous, thermal impact to the peripheral components is restrained. - High Reproducibility

Digital PID control enables good reproducibility of temperature and time. As a result, no skill of the operator is required.

- Pb Free Compatible

Pb free solder is accommodated by setting to high temperature and long heating time.

- User Interface

RS-232C&I/O is standard equipped, making the unit easy to be connected to external equipment such as incorporating into an automated system.

- Various monitoring functions

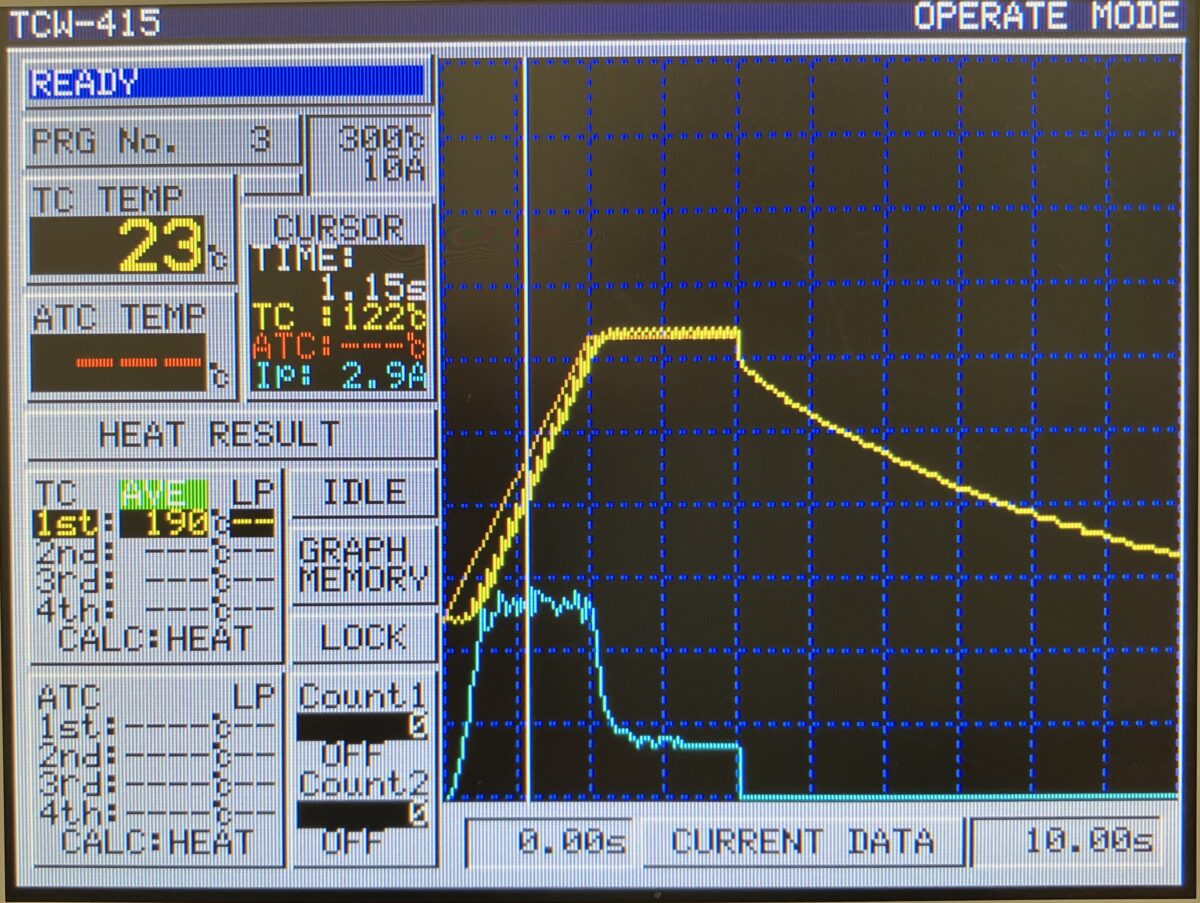

Temperature monitor (Average value, peak value)

Anomaly detection (Excessive temperature rise, thermocouple disconnection)

New Features

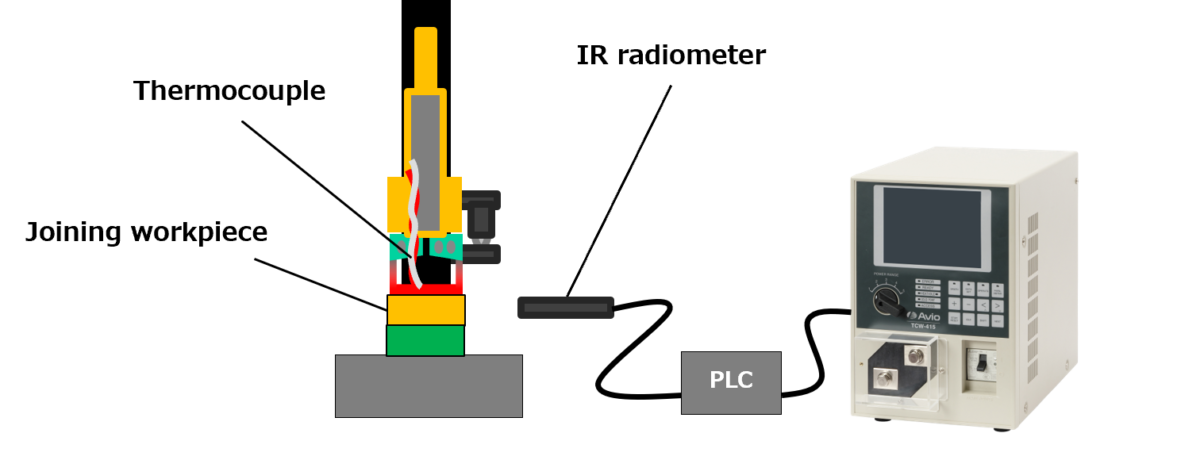

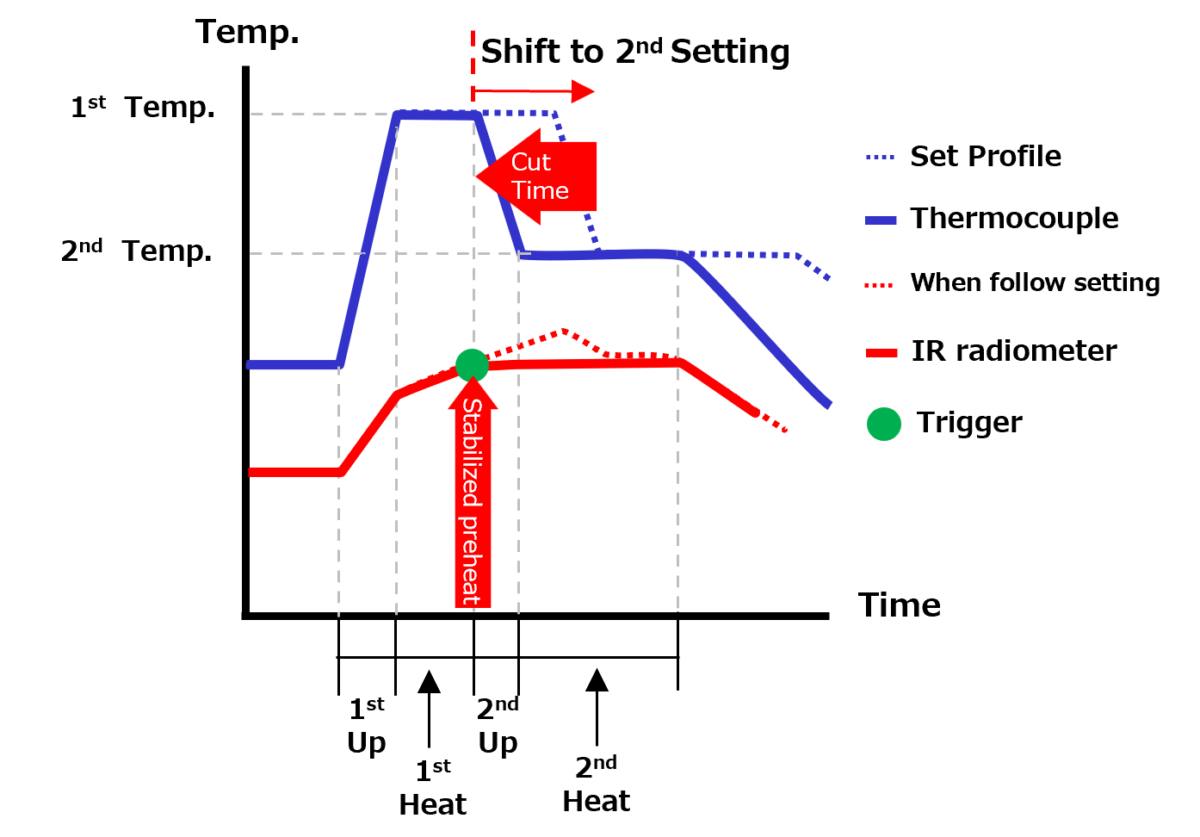

- Heat shift function(A function to switch control parameters based on the temperature of the object being joined)

- Number of heat control steps(4 steps)

- The addition of the after-heat setting has enhanced release properties in plastic staking.

- Control conditions can be switched by using signals—such as those from displacement sensors—input through external I/O as a trigger.

- Temperature waveform can be plotted up to the completion of cooling

- The newly added current value display function enables easy power consumption management through calculation of the consumed power.

Other functions

- Setting condition memory (255 conditions)

- Electric valve control for heater tip, heater tool

- Auxiliary thermocouple monitor

- CE conformity(optional)

Heat shift function

The temperature of the workpiece serves as a trigger to switch control conditions.

Application example

- For substrates with high heat dissipation, the transition to the main heating temperature is triggered by reaching the preheating temperature, thereby stabilizing the temperature at the start of main heating.

- For substrates with low heat resistance, the transition to the next heat condition is triggered by reaching the heat resistance temperature, thereby reducing thermal impact on the substrate.

Shift control settings triggered by temperature of joining workpiece

Pulse Heat (Hot Bar) Soldering Power Supply Specifications

| Items | TCW-415 |

|---|---|

| Heating temperature | Room temperature 〜 600℃, 1℃ step(E,J TYPE) Room temperature 〜 900℃, 1℃ step(K TYPE) |

| Thermocouple Type | E, J or K type |

| Heating time | 000-999 ( x 100ms, x 10ms) |

| Transformer Rated Capacity | Built-in, 750VA |

| Transformer Secondary Voltage | 0.88V、1.24V、1.75V、2.47V、3.5V |

| Heat Control | 4 steps |

| Display Screen | 5.7“ color LCD |

| Monitor Function | Temperature from main and auxiliary thermocouple |

| Interface | RS-232C, I/O |

| Power source | Single phase AC200V ~ 230V±10% 15A (Option: AC100 – 115V)* |

| Dimensions | W200 × D320 × H283mm |

| weight | Approx. 20kg |

※ Factory option