Overlap resistance welding of lead wire and stranded wire | wire compacting

- TOP

- Resistance Welding

- Applications of Resistance Welding

- Overlap resistance welding of lead wire and stranded wire | wire compacting

In addition to mechanical connections using crimping terminals, connectors and soldering, resistance welding is used to connect lead wires and stranded wires of thermistors and thermocouples.

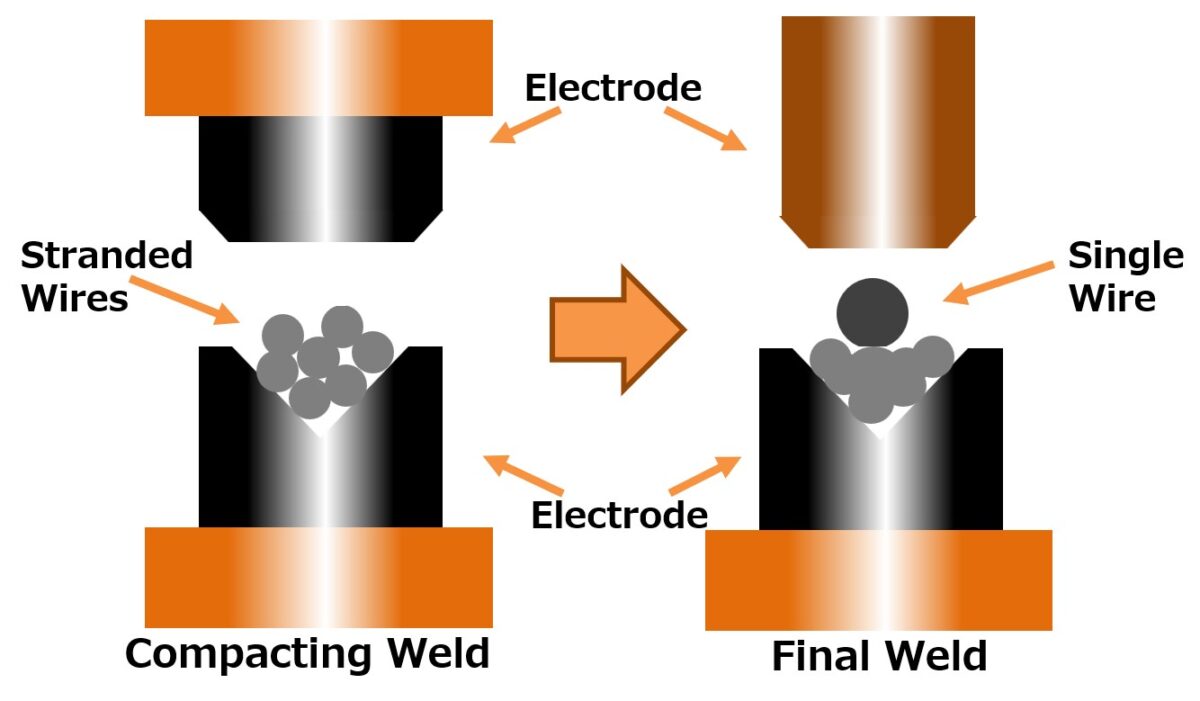

However, resistance welding involves applying pressure to join the wires, which causes the strands to spread and come apart under pressure.

If the stranded wires are joined with the lead wires while scattered, the protruding portions will come into contact, resulting in defects such as short circuit.

One method to solve this issue is by compacting the lead wires to make them more solid.

What is compacting?

When pressure is applied to stranded wire, it flattens, and the wires tend to be scattered and disintegrated. In order to avoid this, compacting is the process of hardening the strands into a rectangular shape.

When joining lead wires and stranded wires, compacting the stranded wires in advance prevents them from coming apart, enabling a stable joint without connection failure.

To perform compacting with resistance welding, use an opposed type welding head that clamps the wires vertically. The V- or U-shaped electrode is placed at the bottom side and clamp wires to solidify them.

Then, compacted strand wire and lead wire are welded.

The compacting prevents the wire from breaking apart, thus eliminating defects such as short circuit.

The challenge with the compacting is that the welding involves two processes and requires two welding power supplies, resulting in high installation equipment costs.

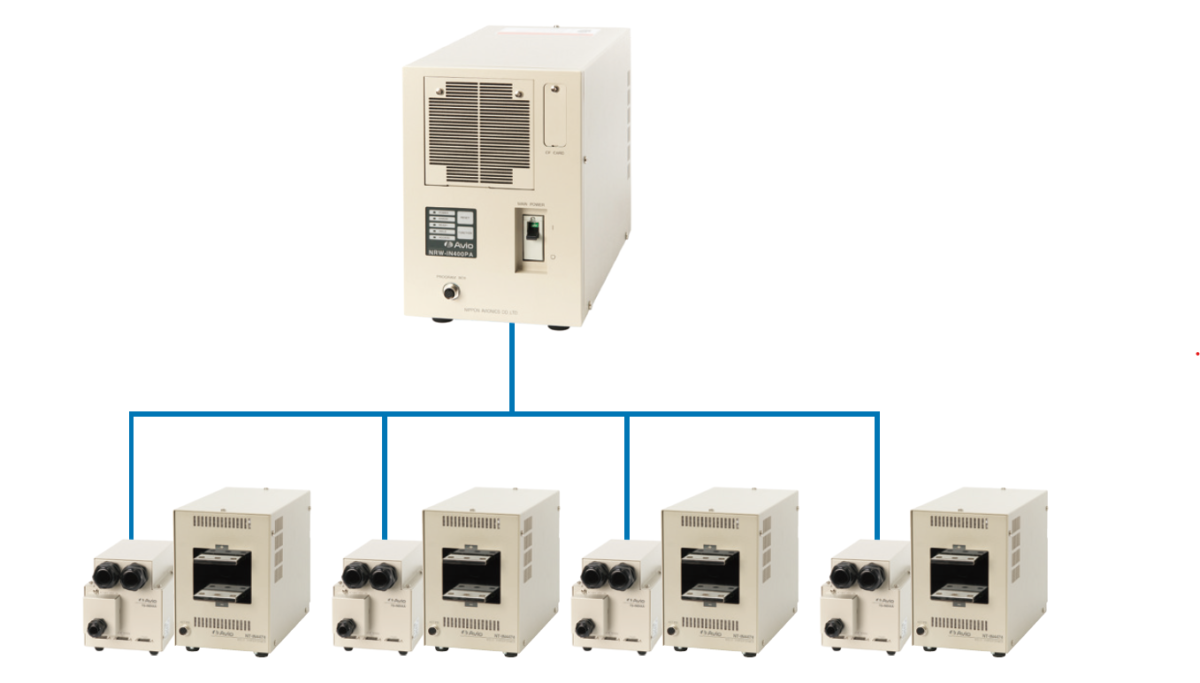

If you use the NRW-IN400PA, only one welding power supply is sufficient.

Avio NRW-IN400PA, an inverter-type resistance welder, is capable of a multi-transformer that can connect up to four transformers from one welding power supply.

The NRW-IN400PA multi-transformer system allows the compacting of stranded wires and welding of stranded wires and leads with a single power supply.

It also saves space because a single power supply can perform two welding processes.

When designing automated system, no need of two welding power supply allows compact system design.

When joining stranded wires and single wires such as lead wires, the compacting is recommended to solidify the stranded wires.

The multi-transformer system of the NRW-IN400PA inverter-type resistance welder enables stable production with low installation costs.

Click here for details of inverter type resistance welder NRW-IN400P

We are currently accepting sample tests for the compacting.

We are capable of performing the compacting of wires as small as 0.3SQ (AWG22).

Please feel free to contact us if you are interested in testing the actual joining condition and strength,