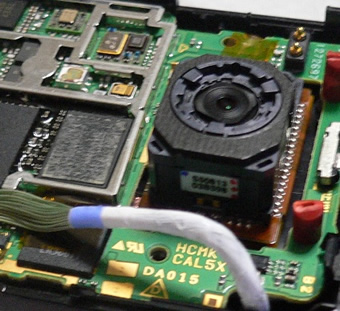

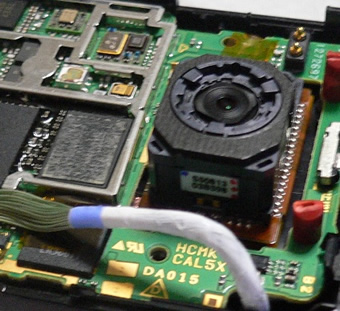

Camera module assembly

- TOP

- Pulse Heat (Hot Bar Reflow) Soldering

- Applications of Pulse Heat (Hot Bar Reflow) Soldering

- Camera module assembly

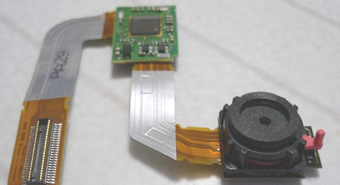

Joining of camera and the FPC (driver circuit)

- When the connection pads are arranged in matrix form, the joining area becomes large, and uniform heat and pressure distribution will be important.

- Because of the local heating, thermal damage to the camera sensor can be kept minimum.

- CMOS or CCD image sensors mounted on mobile phones or digital cameras become camera modules when they are gang soldered onto a FPC by the pulse heating method.

Features of Hot Bar Reflow Soldering / Pulse Heat

When soldering or thermo-compression joining of flexible circuits, such as the TAB or the FPC, highly reliable joining can be realized without lifting up or misalignment by employing the pulse heat method where heating and cooling are conducted while the pressure is being applied.

Camera module assembly

| Joining Method | Pulse Heat (Hot Bar Reflow) Soldering |

|---|---|

| Processing Method | Soldering |

| End Products | Camera |

Sample test

We will be pleased to test your sample with our proposed joining method, and return it with a report.

Related Link

Products

- General Purpose Type Pulse Heat Power Supply TCW-315

- High Power Type Pulse Heat Power Supply PHU-35

- Pulse Heat System Head NA-11 series, NA-15 series