Principle of High frequency induction heating

- TOP

- High Frequency Induction Heating

- Principle of High frequency induction heating

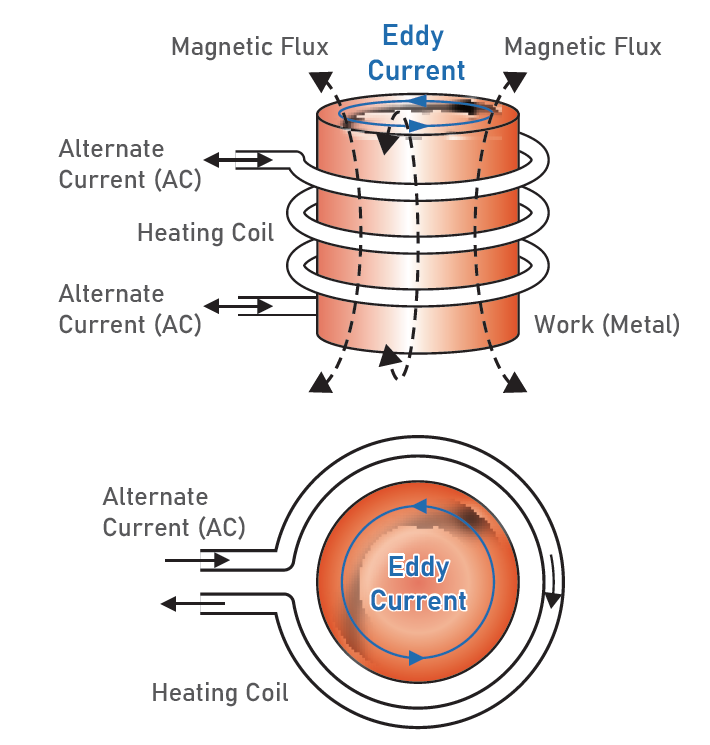

High frequency induction heating is a method of heating metals by self-heating in a non-contact manner using electromagnetic induction.

When an alternating current is applied to a coil with a metal object inside or held nearby, the current flowing through the coil generates a magnetic field, which causes induction loss (hysteresis loss) resulting in heat generation.*1

At the same time, eddy currents are generated in the magnetic field due to electromagnetic induction that is changed by the alternating current.

This eddy current generates Joule heat, which causes heat loss of electromagnetic energy (eddy current loss).*2

High-frequency induction heating systems use two heating principles, hysteresis loss and eddy current loss, to perform heating.

*1: Hysteresis loss occurs only when the object to be heated is a magnetic material.

*2: Eddy current loss occurs both when the material to be heated is magnetic or non-magnetic.

Insertion Procedure

After induction heating of a metal work, push the work against the hole of a molded plastic product using a punch body, and cool it by air.

Melting Margin

- Make the Hole Diameter of a Molded Plastic Product Smaller than the Work by 0.3 - 0.6 mm

- A Screw Guide and a Release Hole for the Melted Plastic will be Required

Resistance Welding

Resistance Welding Hot Bar Reflow Soldering

Hot Bar Reflow Soldering Ultrasonic Welding

Ultrasonic Welding Ultrasonic Metal Welding

Ultrasonic Metal Welding Parallel Seam

Parallel Seam  High Frequency Induction Heating

High Frequency Induction Heating