Hermetic sealing of crystal device and MEMS

- TOP

- Parallel Seam Sealing

- Applications of Parallel Seam Sealing

- Hermetic sealing of crystal device and MEMS

Features of Parallel seam welding

- In parallel seam welding, because the welded area per each welding is very small, low pressure and small welding current will be sufficient, which is suitable for ceramic package.

- In parallel seam welding, welding is made only to the plated layer. Therefore, the base material (kovar) will not be exposed to ambient air, resulting in stable operation over a long period of time.

- Vacuum sealing, where seam welding is conducted in vacuum, is also possible.

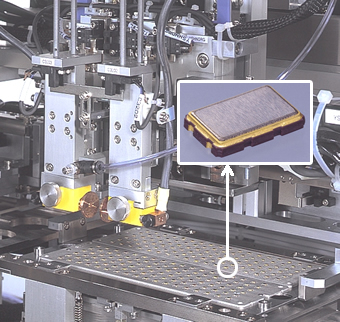

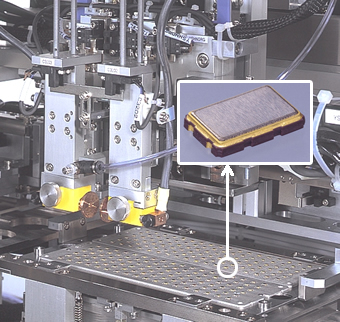

Micro-joining application: Parallel seam welding of crystal device and MEMS.

A lid (metal) is placed on a ceramic package, and hermetic sealing is achieved by parallel seam welding .

Related video

Please be careful for the volume adjustment as this movie contains sound.

Hermetic sealing of crystal device and MEMS

| Joining Method | Parallel Seam Sealing |

|---|---|

| Processing Method | Parallel Seam Sealing |

| End Products | Crystal Device and MEMS |

Sample test

We will be pleased to test your sample with our proposed joining method, and return it with a report.

Related Link

Applicable machine models

- Parallel Seam Sealer: In N2 gas Type/Full Automatic Type

- Parallel Seam Sealer: In Vacuum Type/Full Automatic Type